SHIELDINGS

Marchandise: shields designed according to your specifications

Magnetic Shielding Products

Here you will find an overview of our magnetic shielding products and services. Our effective shielding solutions are very often customized and serve to ensure the functionality and safety of both the sink and the source.

Each of these categories offers a specific solution for different magnetic shielding requirements. Our goal is to provide you with the best possible solution for your specific needs. Our experts are available for a personalized consultation to design the right product for you.

We invite you to continue clicking through our product pages to learn more about our shielding solutions. Be inspired by the variety of our products and don't hesitate to contact us with any questions. Marchandise is your partner for shielding of low frequency magnetic fields.

For special applications in cryogenics, we offer our cryogenic shields made of Cryophy®. This specially developed material offers excellent magnetic shielding properties at extremely low temperatures. Learn more about the advantages and applications of our Cryophy® shields on the corresponding product page.

For larger rooms or industrial applications, we offer customized room and large-scale shieldings. We can customize these solutions to meet your specific requirements, guaranteeing maximum efficiency. Keep clicking to learn more about our room and large-scale shieldings and find the perfect solution for your needs.

Basic magnetic shielding is an essential component to protect your technical devices and protect them from magnetic and electric fields. We design their shields and have them manufactured from specially developed materials that effectively reduce interference, ensuring the function and performance of your equipment. For more information on our specific magnetic shields, please visit the product page.

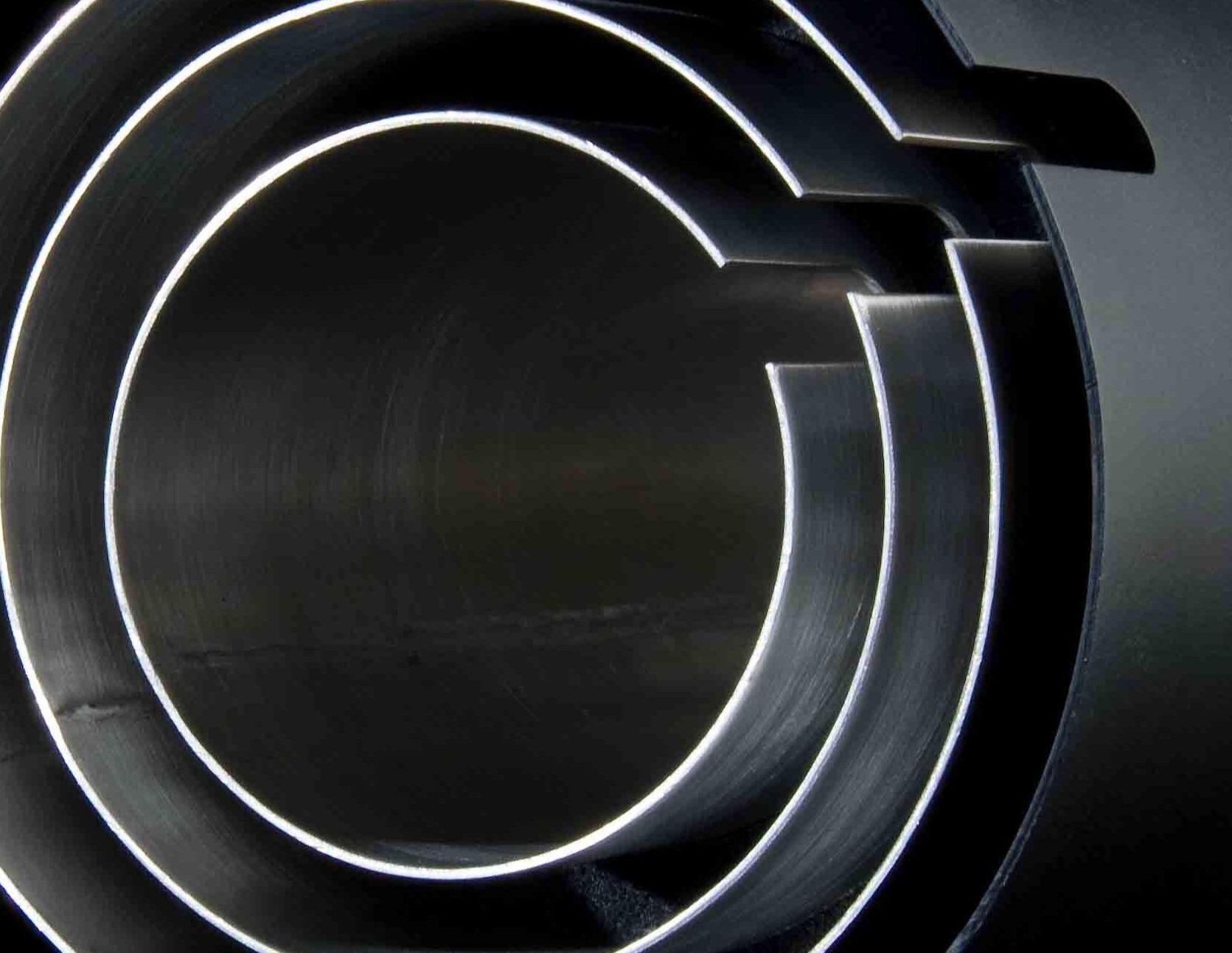

Our zero gauss chambers are used to shield magnetic fields at extremely low residual field levels. These special shields are ideal for useful technical applications where even the smallest magnetic influences must be avoided. Discover more about our zero gauss chambers on the product page.

Low frequency magnetic shieldings

SOLUTIONS FORShielding low-frequency magnetic fields is the most difficult. There are basically two possibilities. One is to increase losses through absorption in the shielding material, the other is to trap the magnetic field in such a way that it is kept away from the zone to be protected. Both methods require materials with high permeability, resulting in increased absorption losses, along with a low reluctance path to concentrate the magnetic flux. For static fields (F=0) only the latter option is used, as there is neither absorption nor reflection. Shields that protect against static magnetic fields are also effective against alternating fields. In contrast to most applications, eddy currents are then advantageous. The most important parameter is the depth of penetration. The attenuation increases with frequency until the increase is offset by the decrease in permeability. Sometimes it is necessary to achieve extremely weak residual fields that cannot be achieved with single-layer shields. Then composite screens with two or more layers are required. Metals with high permeability and high saturation induction (for strong interference fields) are used as materials for magnetic shielding. The calculations must take into account that the permeability varies depending on the operating conditions. The first essential step is to clearly define the conditions under which the shield must operate, in particular:

- Strength, frequency and direction of the interference field;

- the desired shielding factor;

- Shape and dimensions.

This design information is essential for the selection of material and thickness, as well as for deciding whether one or more layers are necessary. Depending on the shield geometry, the design must be based on the equations for the nearest simple shape (cylinder, cube, or sphere). Since the calculations are only approximate values, a correction factor is usually necessary, especially for complex shapes. In fact, magnetic shields are often welded constructions with openings, overlapping sheets, fastening tabs, etc. All these characteristics generate interference that can be compared to air gaps, which always reduce the apparent permeability of a magnetic circuit and therefore the efficiency of the shielding. All standard sheet metal fabrication operations must therefore be carefully considered to balance mechanical strength considerations with the need to minimize the obstruction of magnetic flux. Since the alloys used are very sensitive to mechanical stresses, the shields must be completely finished before the final heat treatment and must not be changed afterwards.